Pre Engineered Buildings

Pre-Engineered Buildings are pre-detailed and pre-designed and are manufactured in a quality controlled factory atmosphere. At this stage each process is carried out employing sophisticated technologies that include the application of advanced welding techniques and standardization of components. Such procedures facilitate mass production.

PEB uses high strength steel for better strength/weight ratio and is also ideal for construction in remote areas and hilly terrains as a major part of the construction activities are carried out at factory level. Most importantly PEBO construction is 30% to 40 % faster than the conventional or masonry construction.

The Many Benefits Of Peb

- Functionally versatile: The clear-span is larger. They range from 40M and above. They have a long bay spacing, which helps in reducing the total number of columns and foundations.

- Architecturally flexible: PEBs offer better systems of metal cladding, and hence, are the perfect choice for aesthetically superior building structures.

- Easy to erect: All the components are field bolted, and therefore, PEBs facilitate fast erection and very easy setting up of multi-deck structures.

- Superior quality: PEBs are earthquake resistant.

- Easy maintenance: They gather less dust and are easy to maintain.

Features Of Peb

Primary Structural Frames

Primary frames are the main load carrying and support members of a pre-engineered building.The PEB rigid frame comprises of tapered columns and tapered rafters (The fabricated tapered sections are referred to as built-up members).

Secondary Structural Frames

Secondary frames includes Purlins,Girts and Eave Struts.These are used to support the wall and roof panels.Purlins are used on the roof;Girts are used to provide framework for wall cladding for sidewalls and endwalls.All eave struts are cold formed C sections well suited at the corners to support sheetings.

Bracings and Fasteners

These are items that are required in every Steel Structure.They include Anchor Bolts,Connection Bolts,Sag Rods and Cable Bracing Components. Longitudinal cross bracing,used to provide lateral stability to the structure against wind,seismic or other forces

Mezzanine floors

The mezzanine framing is connected to the main rigid frame columns for lateral,stability. Standard mezzanine structure consists of built-up beams that support built-up,hot-rolled or cold-formed mezzanine joists which in-turn support a metal deck. A reinforced concrete slab is cast on the metal deck as a finished surface.

Configuration Of Peb

- Built up sections are welded and used for the design of steel framing structures.

- The Purlins, which are the roof framing structures, and the runners are constructed as Z-formed sections or C-formed sections.

- FASCIA are provided at the eave level of the roof. This action safeguards the roof and imparts a show-room like appearance to the construction.

- Profile steel sheets that are colour coated and galvanized, and have a thickness of about 0.5 mm, are used to cover the sides and roofs.

- Self-tapping screws are then used to fix the steel sheets with the runners and Purlins.

- To insulate the structure, a layer of glass wool or rock wool is inserted under the roof sheet. This layer has to be 50 mm thick.

- The side and end walls are fitted with steel sliding doors and aluminium windows, if needed.

- To install sky panels on the roof, FRP (Fiberglass Reinforced Polyester) sheets are introduced. These FRP sheets should be of a standard dimension of 1.0 M X 3.0 M.

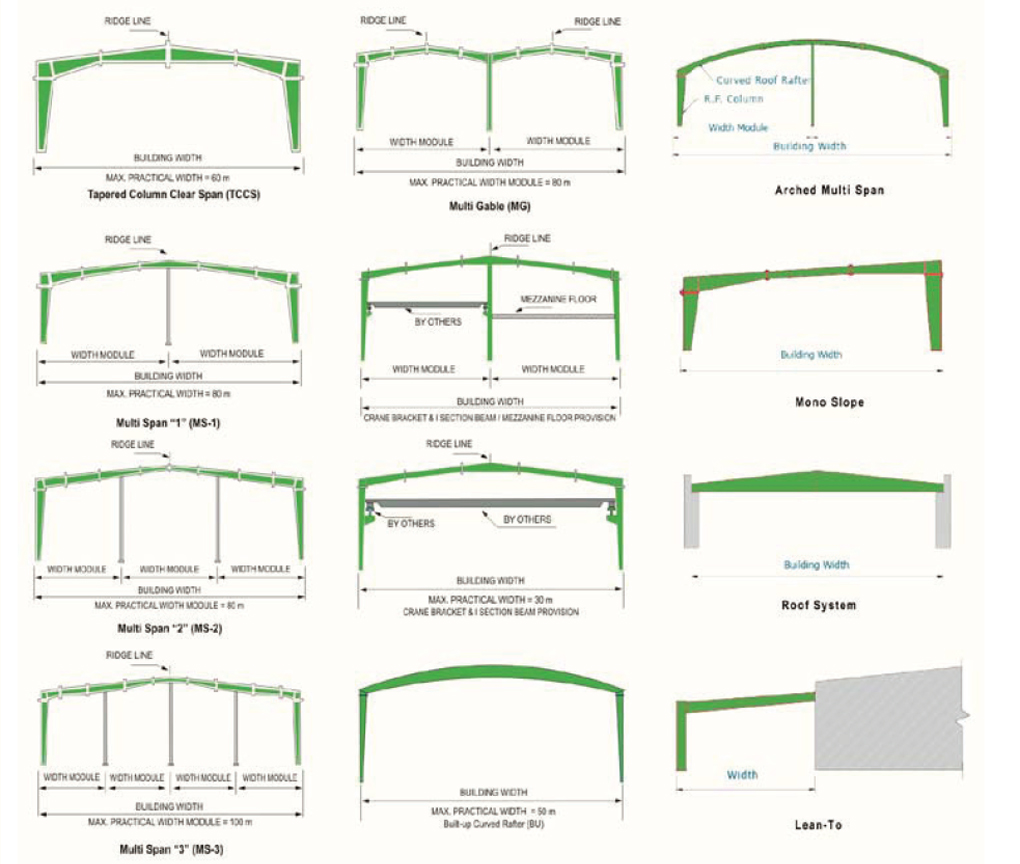

Pre Engineered Buildings Types

Advantages of Pre Engineered Buildings

Reduced Construction Time

Buildings are typically delivered in just a few weeks after approval of drawings.Foundation and anchor bolts are cast parallel with finished,ready for the site bolting.The use of PEB will reduce total construction time of the project by at least 50%.This also allows faster occupancy and earlier realization of revenue.

Lower Cost

Due to the systems approach,there is a significant saving in design,manufacturing and on site erection cost.The secondary members and cladding nest together reducing transportation cost.

Flexibilty Of Expansion

Buildings can be easily expanded in length by adding additional bays. Also expansion in width and height is possible by pre designing for future expansion.

Large Clear Spans

Buildings can be supplied to around 80M clear spans.

Quality Control

As buildings are manufactured completely in the factory under controlled conditions the quality is assured.

Low Maintenance

Buildings are supplied with high quality paint systems for cladding and steel to suit ambient conditions at the site,which results in long durability and low maintenance coats.

Energy Efficient Roofing And Wall Systems

Buildings can be supplied with polyurethane insulated panels or fiberglass blankets insulation to achieve required"U"values.

Architectural Verstality

Building can be supplied with various types of fascias,canopies,and curved eaves and are designed to receive pre cast concrete wall panels,curtain walls, block walls and other wall systems.

Single Source Responsibility

As the complete building package is supplied by a single vendor, ACV compatibility of all the building components and accessories is assured. This is one of the major benefits of the pre engineered building systems.

The Following Machineries Are Available At Our Three Different Production Units To Facilitate Production Of Our Multi-products

- Multi Nozzle CNC Plate Cutting Machine

- Automatic Beam Assembling Machine (Beam Line)

- Trans Synergic MAG Machine

- CNC Special Purpose Machine

- MZ 1000Bx2 Door Shaped Welding Machine

- HYJ-40H Steel Flange Correcting Machine

- Fully Automatic CNC Multi cutter Machine

- Automatic Multi Nozzle Submerged

- Wielding Machine

- Bail Press

- Tapping Machine WMW

- Jib Crane

- EOT (overhead crane) 5MT

- Lathe 6 ft

- Lathe 12

- Shearing Machine 400 MT with 4mts, bed

- Shearing Machine 250 MT with 4mts, bed

- Circular Saw Cutter

- Pug Cutter

- Hacksaw Machine

- Hand Shearing Machine

- Gas Cutting Sets

- Universal Cropping Machine

- Power Press 40MT to 120 MT

- Riveting Machine

- Material Handling Equipments

- Forklift 3Tons

- Press Brake 300Mt with 4mts Bed

- Press Brake 250MT with 3mts Bed

- Spot Wielding Machine

- Mig Wielding Machine

- Welding Machine (Rector type)

- Bench Grinder

- Pillar Drilling Machine

- Portable Drilling Machine magnetic base

- Turret Drill

- Radial Drill

- Earth Excavator/Dozer (JCB)

- Hydra 12M

- Hydra 8M

- Semi Automatic Submerged Arc Wielding Machine (SAW)